A Moment in Time

This film highlights the changes that have come about in the industry over the past 20 years and continues to support the reality that the future of horology is now in the hands of the independent.

Assembling a Bracket Clock - Part 3

The most recent three videos have made up a three-part series covering the reassembly procedure of a large 19th century quarter chiming bracket clock as part of a recent overhaul. The third part was released just minutes ago so click on the picture below to watch it.

Assembling a bracket clock - Part 2

Part 2 of this short series of videos covering the assembly of a quarter chiming bracket clock movement. In this video, I lubricate the trains and set up the fusee chains.

Assembling a Bracket Clock - Part 1

Part 1 of a 2 part series covering the reassembly process of the repair to a wonderful 19th-century bracket clock. The clock is quarter chiming with three trains driven by chain fusees.

Making a Fusee Stopwork Snail

This is the final part of the short series covering the repair to the skeleton clock fusee. In this video, I complete the repair by making a new stop-work snail.

Cutting a Clock Fusee Thread.

In this video, I continue with the repair to this skeleton clock fusee. In the previous video, I removed the old repair and turned and fitted a new repair section out of cast ‘yellow’ brass. In this video I go on to cut the thread on the repair section, matching it to the pitch of the existing thread.

Repairing a clock fusee

This Tuesdays video is the first part of a short series where I repair a fusee from a month going skeleton clock.

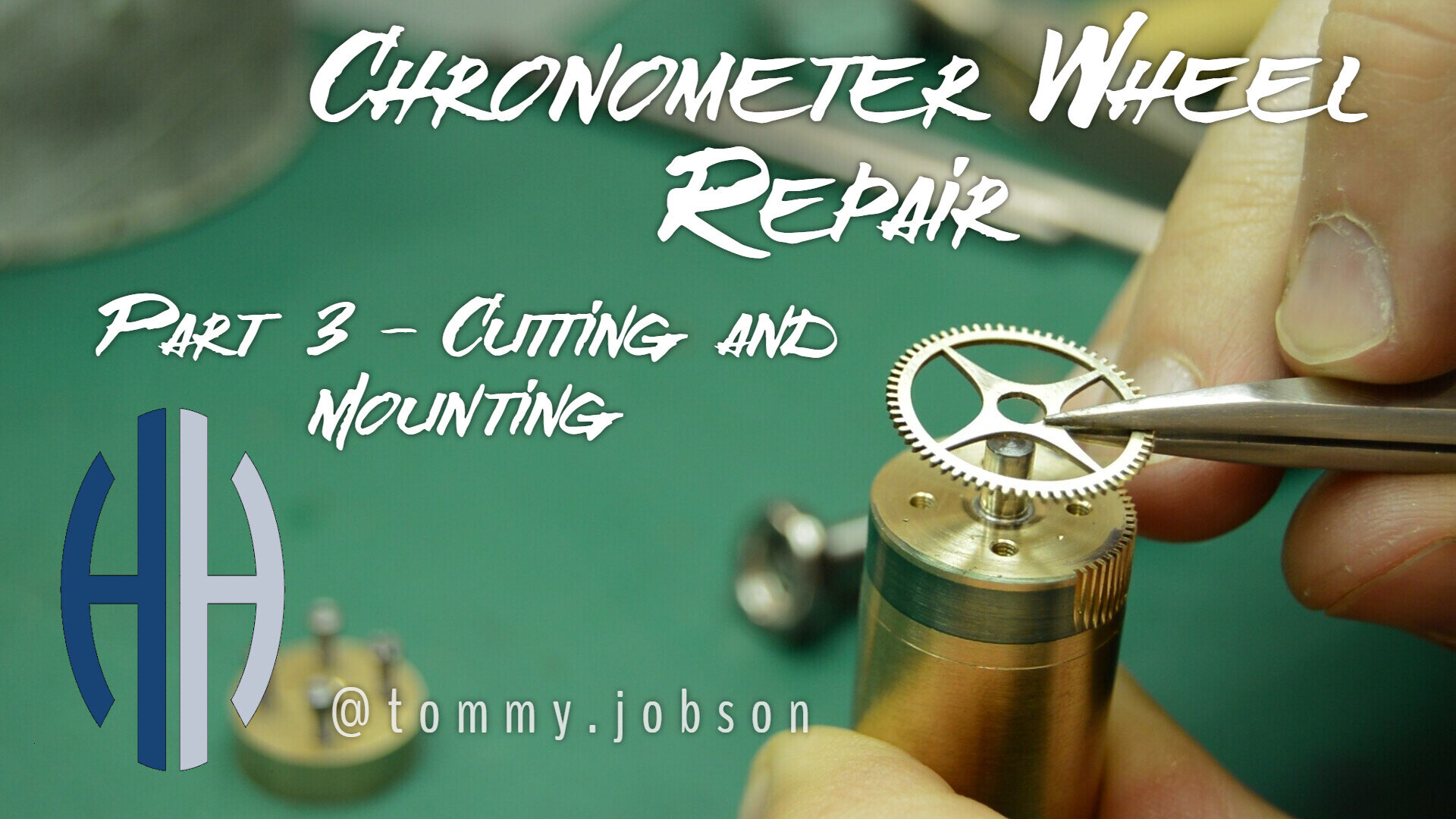

Part 3 of the Chronometer train wheel repair series.

Part 3 of 3 of the repair to the Chronometer train wheel. In this video I cut the teeth using the holder made in a previous video mounted in the Scvhaublin 102 lathe. I then re-fit the wheel to the arbor.

Chronometer Train Wheel Repair Part 2 - Setting Up

In this video I focus on setting up the machine ready to cut the teeth.

Reverse Engineered Clock Part. Trade Secrets Episode 2

Following on from Episode 1 where I used Fusion 360 to reverse engineer the design of this clock part, in episode 2 I complete the manufacture of the part. A really useful way of using modern technology in traditional clock repair and restoration.

Chronometer Train Wheel Repair

A major restoration of a Barraud chronometer included repairing damage to a train wheel. This is part 1 where I asses the work and make a holder which enabled me to machine new teeth on the repaired section of the wheel.